We don't just supply raw products, but finished in detail. finished in detail.

A wide range of customized processes and additional services.

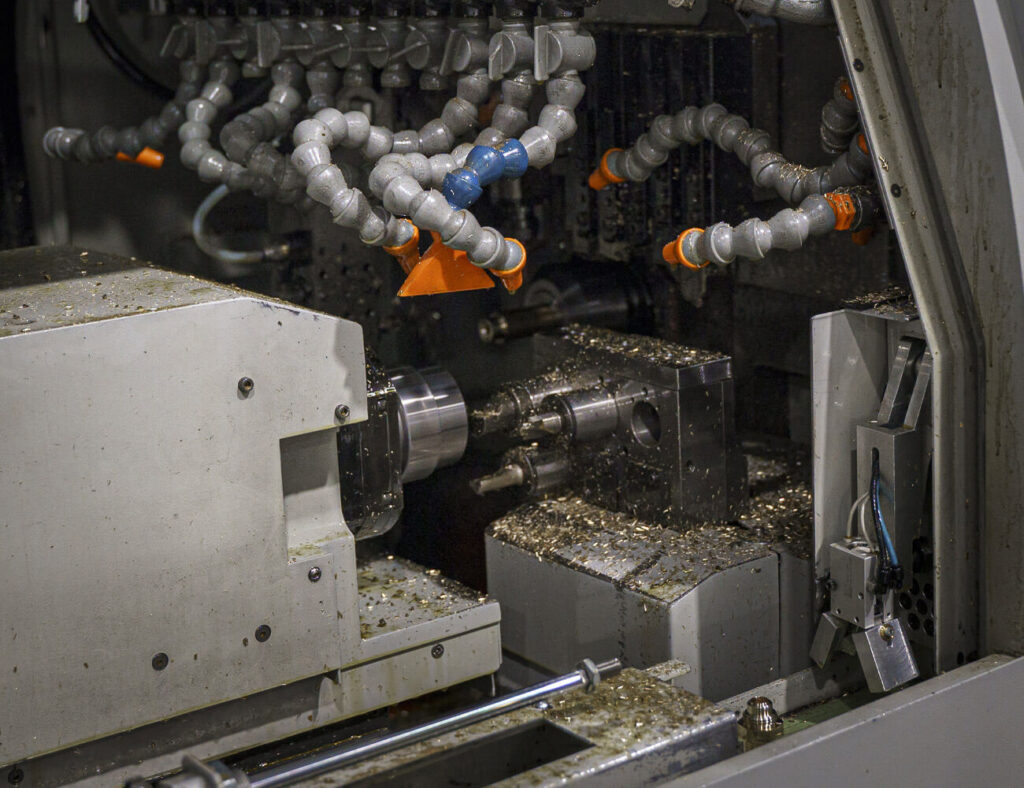

Double type of machine, we work pieces from small to large diameter and for different industrial sectors.

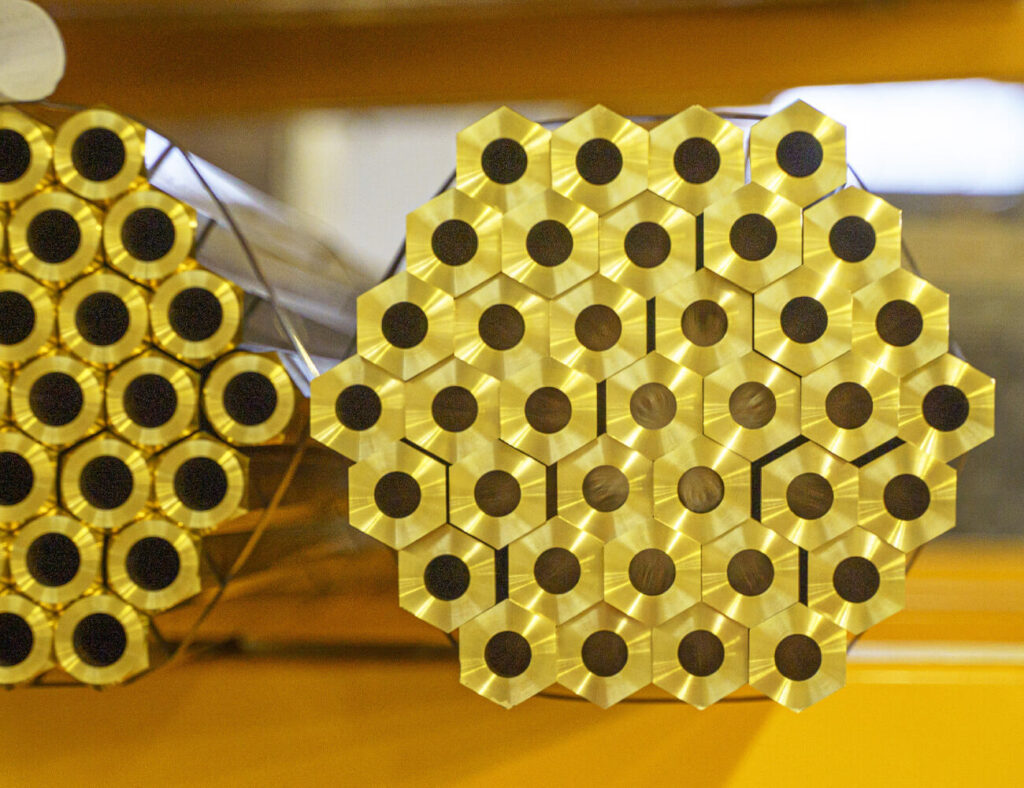

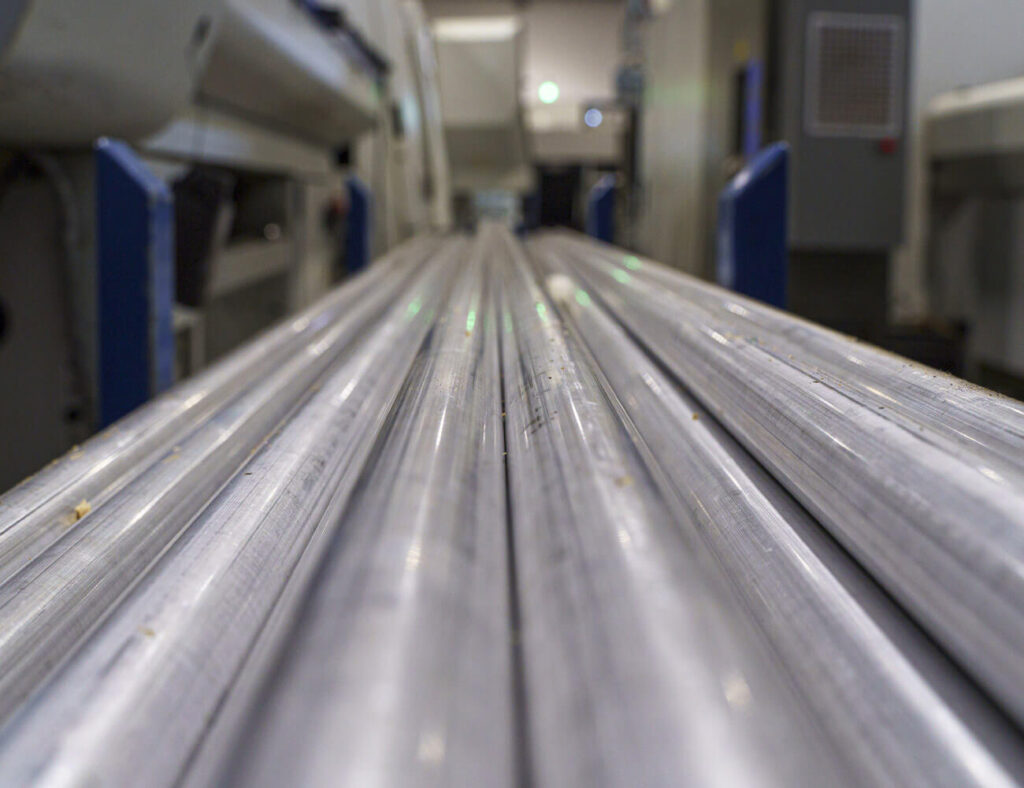

We are able to tackle the most sophisticated production processes on various diameter dimensions (from ⌀4 mm to ⌀75 mm, without excluding the hexagonal bar) thanks to a well-equipped and cutting-edge machine park, consisting of multi-spindle mechanical lathes and CNC machines sliding headstock and fixed headstock.

Wherever there is a need to use high precision turned parts, LMC is a secure support and a reliable supplier, regardless of the place and type of use of the turned part to be produced.

Propose your project to us, we will find the best solution for you.

One last check: the packing phase.

It is not only the final phase but it is an integral part of the production cycle and for this reason it is a very important phase for us: it is a last visual check!

The packaging of the products is carried out with the utmost care, to guarantee the quality of the product and to allow easy handling of the goods within your warehouse.

Upon request, we can carry out the packing of the pieces one by one in order to avoid any slight dents during storage. It is carried out by our operators, in various ways, inside boxes of various sizes and also through the use of pallets (if required), or in bulk, or still in open boxes, always according to the specific requests.

Materials.